Press, Articles

New Algorithm Enhances PEC Accuracy in High-Voltage Inspections

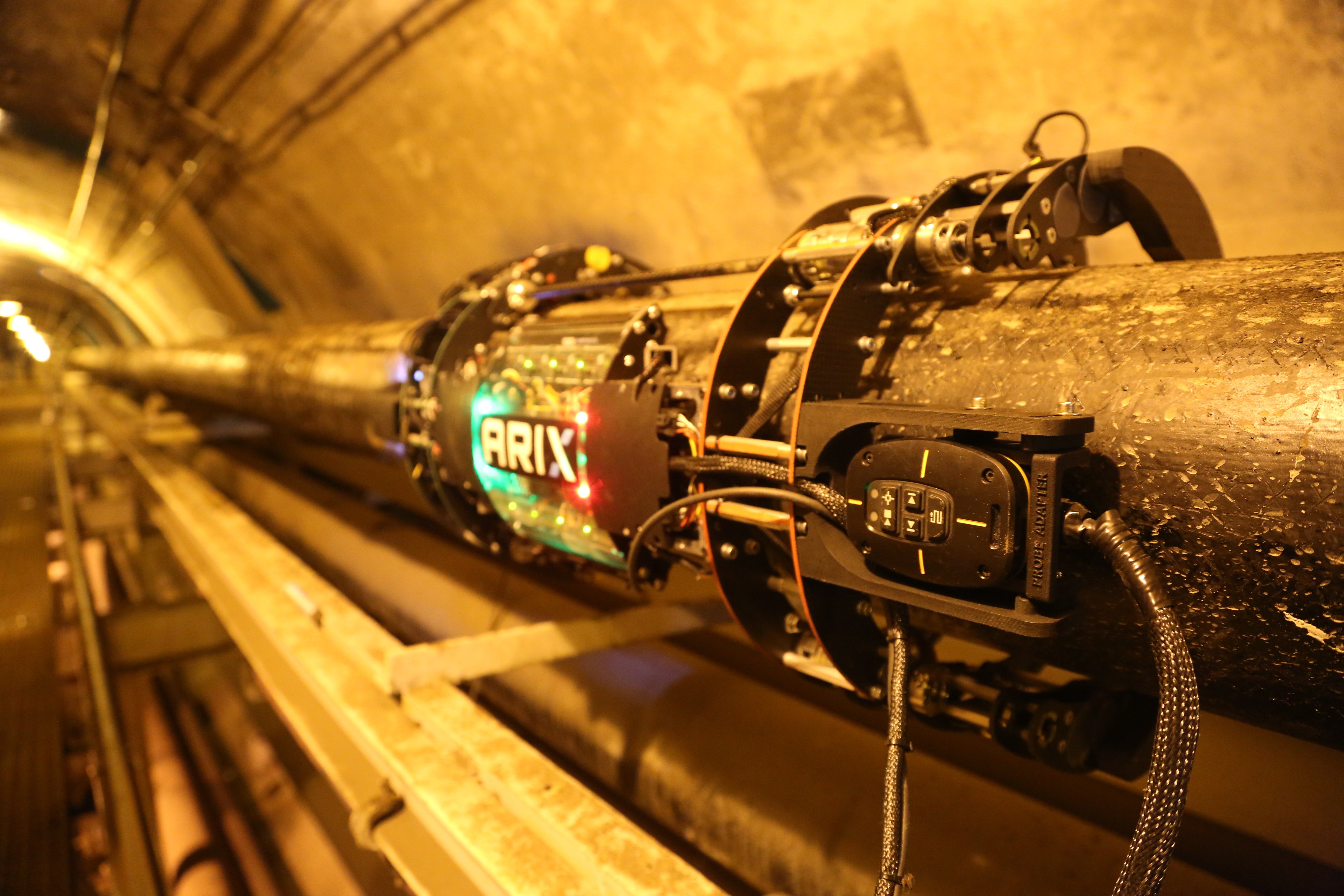

ARIX's Director of Engineering, Petter Wehlin, has co-authored a pioneering study with researchers Xuhui Huang, Vijay Srinivasan, Josephine Aromando, and Yiming Deng that revolutionizes the accuracy of pulsed eddy current (PEC) inspections in high electromagnetic interference environments.

Industrial facilities face significant challenges when inspecting high-voltage feeder cable pipes using traditional PEC methods. The strong electromagnetic fields from internal power lines create variable magnetic permeability in the pipe walls, leading to inaccurate thickness measurements and potentially costly false positives.

Solving a Critical Industry Challenge

The research introduces a novel data-driven auto-compensation algorithm that effectively corrects distortions in PEC measurements caused by electromagnetic interference from power lines. This groundbreaking approach combines:

- Advanced physics-based modeling of electromagnetic interactions

- Finite element method (FEM) simulations

- Machine learning techniques using Gaussian Process Regression

"This technology directly addresses one of the most persistent challenges in industrial inspection," said Petter Wehlin, Director of Engineering at ARIX Technologies. "By accurately compensating for electromagnetic interference, we're enabling more reliable asset integrity assessments without costly insulation removal or production interruptions."

Field-Validated Results

The algorithm has been extensively tested in real-world conditions, demonstrating:

- Significant reduction in false-positive indications

- Enhanced measurement consistency across varying electromagnetic conditions

- Rapid computation time, enabling practical field applications

This collaborative research between ARIX Technologies and academic partners contributes to the company's continued commitment to advancing non-destructive testing through innovative technologies that improve safety, efficiency, and reliability in industrial settings.

Read the full research paper published in Nondestructive Testing and Evaluation

Related Resources

Press, Articles

ARIX Technologies Expands into the GCC with 01Lab Partnership

ARIX Technologies Expands into GCC with 01Lab Partnership

Safety, Articles

API 570 & CUI: Guide to Piping Inspection & Corrosion Prevention

Learn about API 570 in-service piping inspection, repairs, and CUI (Corrosion Under Insulation) prevention. Explore advanced robotic inspection solutions!

Articles, Case studies

Petromax Refining Achieves 7x Faster, 37% Cheaper CUI Inspections with ARIX Robotics

ARIX helped Petromax Refining achieve 7x faster CUI inspections while reducing costs by 37%—a game-changer in industrial asset management.

Get in touch with us!

Want innovative solutions to increase safety, lower costs, and preserve your equipment for years to come?

Let’s Talk